Turning carbon into concrete could win UCLA team a climate victory â and $7.5 million

Gabe Falzone and his teammates had been up since 5 a.m., anticipating the arrival of the concrete mixer. When the truck pulled into the alley behind UCLAâs Boelter Hall, hundreds of narrow red cylinders stood ready. The engineers scrambled to fill the containers with roughly 8 tons of wet sludge before hustling them into giant ovens in the basement.

They had just 24 hours to complete the next task: bathing the concrete in carbon dioxide to lock away the gas in the worldâs most widely used construction material. This was the critical step in the semifinal challenge of a contest with a $7.5-million payout.

For the record:

9:59 a.m. Jan. 16, 2020An earlier version of this story said the winners of the Carbon XPrize competition would earn a $6.5-million payout. They will receive $7.5 million.

âIt was down to the wire,â said Falzone, a project scientist at the Westwood campus.

The UCLA team is one of 10 vying for the NRG COSIA Carbon XPrize, an international competition to see who can turn the most CO2 into valuable products.

The idea is gaining momentum as a promising climate solution. Called carbon utilization or carbon conversion, it involves taking CO2 emitted by power plants, steel factories, breweries and other industrial facilities and converting it into something practical â and profitable â rather than letting the greenhouse gas escape into the atmosphere.

âItâs very hard to incentivize people to just do things out of altruism,â said Emily Carter, an expert on sustainable energy technologies at UCLA. But âif people can make money,â she said, âitâll happen without government intervention.â

Studies suggest that, in a best-case scenario, converting carbon into useful goods could mitigate 1% to 15% of global emissions, and a 2019 report by the National Academies of Science, Engineering, and Medicine affirmed that it could help tackle climate change by turning a pollutant into profit.

âIt almost sounds too good to be true,â said Marcius Extavour, executive director of the Carbon XPrize contest.

::

Researchers have spent decades studying how to capture CO2 from sources like coal plants so they could pump it into deep geologic formations, where â hopefully â it would stay put for centuries or longer. Thereâs just one problem, Extavour said: âIt doesnât make anybody any money.â

So scientists started exploring ways to turn CO2 into things people were willing to pay for.

Some are piping it into greenhouses to nourish plants, or using it to grow algae for biofuels and animal feed. CO2 already serves as a raw ingredient for many industrial processes, and researchers are developing techniques to incorporate recycled carbon into materials like plastics, polymers, nanotubes â even vodka.

These uses provide an alternative fate for the gas, which would otherwise warm the planet. CO2 is the primary driver of human-caused climate change and the culprit behind ocean acidification.

To halt these trends, society will have to drastically reduce its production of greenhouse gases. But in the meantime, carbon utilization could put some of that CO2 to work.

âThereâs an opportunity to really make the circular economy happen,â said Jennifer Dunn, a chemical engineer at Northwestern University who contributed to the National Academies report. With each of these new approaches, âweâre making a usable product.â

Like concrete.

Using recycled carbon was a no-brainer to Gaurav Sant, the civil engineer who leads the UCLA team. The key binding ingredient in concrete is cement, which has a massive carbon footprint. The cement industry accounts for approximately 8% of global CO2 emissions, and if it were a country, it would be the worldâs third-largest emitter.

Cement is made by heating limestone with other elements. About half of cement-related emissions come from the energy needed to run kilns at scorching temperatures, and these emissions could be avoided by switching to renewable power. But the other half is given off during chemical reactions involving limestone and canât simply be eliminated.

So Sant and his team set to work on a greener approach that starts with a compound called portlandite instead of traditional Portland cement.

The production of portlandite also releases CO2. But its unique chemistry allows it to absorb CO2 later in the process, when the concrete cures and hardens into precast blocks and other shapes. Sant says the method releases 75% less carbon than conventional techniques and can store waste CO2 too.

At first, the researchers worked with tiny quantities of green concrete in the lab. âWe literally produced a thimbleful of stuff,â Sant said.

The challenge was coming up with a recipe that would scale. They had to find just the right mix of ingredients, the right curing temperature, and the right flow of CO2. Sant compared it to baking a souffle.

By now, team members have cooked up more than 100 tons of the stuff. Theyâve even spun off a company, CO2Concrete, to market the technology to the construction industry, which consumes 20 billion tons of concrete each year.

âThereâs no other material that we produce or use in a larger quantity,â Sant said.

::

There is, of course, one thing we make more of: CO2. Every year, society emits roughly 40 billion tons of the gas.

âAs human beings, you could say CO2 is almost, like, our No. 1 product,â Extavour said.

If all the concrete in the world were made of CO2Concrete, it could store about 1 billion tons of CO2 per year, Sant estimates.

Several other types of carbon utilization could theoretically absorb a similar amount, according to a recent analysis in the journal Nature. But few seem as sure a bet as concrete.

Take recycled fuels. Several research groups, including a Canadian team in the XPrize competition, are using captured CO2 to make fuels for cars and planes. So far, however, they cost much more than traditional fossil fuels â and thatâs not their only problem.

Turning CO2 into fuel requires a lot of energy, and securing a clean supply means ramping up renewable sources that might better be used offsetting fossil fuels directly, said Ed Rubin, who studies engineering and public policy at Carnegie Mellon University.

And thereâs another hitch: Storing CO2 in recycled fuels only delays emissions, since the gas winds up in the atmosphere when the fuel is burned.

Such forms of carbon utilization arenât a good use of the limited time we have to address climate change. Niall Mac Dowell, who studies energy systems at Imperial College London, warns they could be a âcostly distractionâ from the real task of reducing emissions.

âYou really havenât done anything, you just think youâve done something,â he said.

::

Some researchers say short-lived products still offer climate benefits as long as they have a smaller carbon footprint than their conventional counterparts, or if they reduce the need to extract new fossil fuels. âThat can still be a win,â Dunn said.

And though products like vodka and pens made from captured CO2 wonât make much of a dent in global emissions, they help raise awareness about the potential for reusing carbon waste, she said.

Proponents also argue that carbon utilization offers a way to capture emissions that canât â or wonât â go away any time soon. Thatâs why fossil fuel companies and other carbon-intensive industries are some of its biggest supporters. (A case in point: The Carbon XPrize is sponsored by the energy company NRG and COSIA, a coalition of Canadian oil sands producers.)

Sant thinks carbon utilization could be especially valuable for sectors like manufacturing, where it will be hard to eliminate emissions completely.

âWe know what to do with transportation. We know what to do with renewables and the grid,â he said. But heavy industry? âBig question mark.â

At least everyone agrees that putting CO2 in concrete makes sense. The product lasts a long time, and demand is projected to skyrocket as cities grow. In fact, the UCLA team has several competitors in the field, including Carbicrete and CarbonCure, another Carbon XPrize contender.

The trick is not just to store CO2, but do it profitably. âThis is not a question of what is possible, itâs a question of whatâs affordable,â Sant said.

His group can already make concrete at costs that compete with traditional precast blocks, he said. Now the engineers need to scale up production, which theyâll do this spring at the XPrize finals.

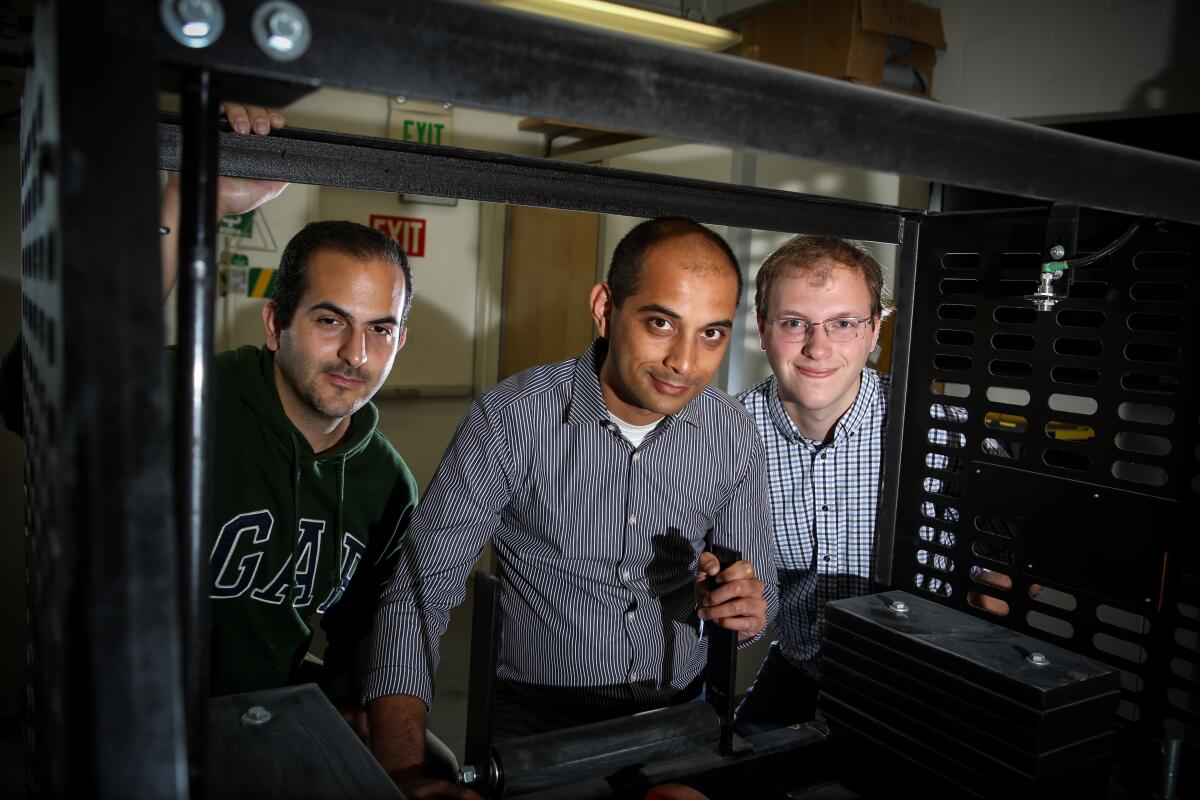

The Bruins earned their spot with their red cylinder demonstration. So in March, Falzone and fellow project scientist Iman Mehdipour will move to Gillette, Wyo., for the better part of three months to put their methods to the test at a coal-fired power plant. They will be judged on the amount of carbon stored and the value of the products created.

Instead of cylinders, theyâll make standard masonry blocks. Each 33-pound brick holds about 400 grams of CO2, and they aim to produce 800 a day. That would sequester more CO2 than a car would emit driving from Los Angeles to Salt Lake City.

The team will find out in September how they fared against the other finalists. The XPrize Foundation, based in Culver City, will crown one winner from the coal plant and another among a group of teams competing at a natural gas plant in Alberta, Canada.

For Sant, itâs as much about proving a point as winning a prize. And the point is that we need to start getting serious about solutions to the climate challenge.

âWe have a tendency to look at everything in terms of its problems first rather than its opportunities,â he said. âWe have to invert that thinking.â